Struggling to remain afloat

Shropshire's automotive component industry is being crippled as the global recession hits the world's car manufacturers. Business Editor Amy Bould lloks at how thousands of jobs hang in the balance as the car parts industry feels the squeeze.

In this special report by Business Editor Amy Bould we see how thousands of jobs hang in the balance as the car parts industry feels the squeeze

In this special report by Business Editor Amy Bould we see how thousands of jobs hang in the balance as the car parts industry feels the squeeze

Shropshire's automotive component industry is being crippled as the global recession hits the world's car manufacturers.

Thousands of jobs have already been lost across the country and more than 300 automotive workers in Shropshire and Mid Wales are being made redundant.

Hundreds of others, including the workforce of Denso in Hortonwood, which employs 900 people, are waiting to hear their fate as consultations are carried out between bosses, workers and unions with a cloud of uncertainty over their long-term employment.

The global downturn has seen the major manufacturers cut their production and workforces. Nissan has cut 1,200 jobs at its Sunderland plant and had a two-week shutdown at the end of 2008. Jaguar Land Rover cut 450 jobs, with a series of one-day shutdowns and production cuts.

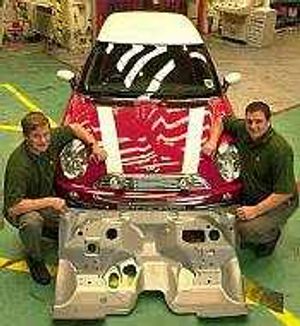

Honda is on a four-month shutdown between February and May and Toyota has also announced cuts, suspending one of its night shifts. Mini announced 850 job cuts and GM (Vauxhall) had an extended Christmas closure and a 40-day shutdown.

The Government has already announced a major package of help for the UK's ailing car industry, including £1 billion of direct loans and a national strategy to help British manufacturers meet demand for greener, cleaner cars.

Beleaguered manufacturers

Lord Mandelson also unveiled guarantees for £1.3 billion in loans from the European Investment Bank in January, but the Business Secretary said that there was "no blank cheque on offer" and no operational subsidies.

Wrekin MP Mark Pritchard has spoken to ministers about the package, which he believes will not help the county's beleaguered manufacturers.

He said: "I was there when Lord Mandelson made his speech and then wrote to manufacturers asking them if there was any help for them in the package announced.

"The feedback was that despite the fanfare and the hype, there are no real elements in the package which can produce real help to save jobs. Jobs in auto-manufacturing are vital to Shropshire's economy and community, and the Government needs to take action to save jobs before it's too late."

GKN Autostructures at Hadley Castle in Telford has announced 150 job losses in addition to the 90 lost in November last year which the company said was down to a nosedive in orders from Land Rover, one of its biggest customers.

GKN Autostructures at Hadley Castle in Telford has announced 150 job losses in addition to the 90 lost in November last year which the company said was down to a nosedive in orders from Land Rover, one of its biggest customers.

The company, which employs 6,400 workers in the UK including 950 at Telford, is restructuring as part of a bid to make savings of more than £2.2 million, with bosses saying each job lost in November represented a saving of £25,000.

Chief executive Nigel Stein said the losses were "absolutely necessary" to respond to the global economic downturn.

"We are in unprecedented times and we must protect our position as a leading global automotive supplier and ensure we are in a strong position to meet our customers' needs now and when the markets recover," he said.

Volumes down

This month, component manufacturer Denso said jobs were under threat after falling sales led to a decision to carry out a review of the company.

Denso Manufacturing UK (DMUK) said it was about to carry out a three-month consultation about the plans to restructure the firm which employs almost 900 people at its Hortonwood base. The company, which would not confirm how many jobs could go and has been in the town since 1992, produces radiators and air conditioning units.

Alan Taylor, head of human resources at Denso, said volumes were down about 50 per cent on six months ago.

"We are in a difficult position because the car industry is being hammered and with the recession being global, we are seeing the impact in every area."

Mr Taylor added: "We do not anticipate the volumes will come back. Our corporate belief is that volumes will level and slowly recover, but certainly in Europe as a region, the volumes won't come back to 2007 levels even by 2011 or 2012."

The company is part of the Acertec car parts firm which supplies, among others, BMW for the Mini, Aston Martin, Bentley and Jaguar Land Rover.

Sales and marketing director Dinos Andreou said the company's global headcount had been reduced by about 37 per cent.

He added: "We reacted with that plus a whole host of other measures to bring down costs in the business, which is a natural reaction to the decline in the industry.

"We believe we have a business operating in a steady state, we have sized the workforce according to the customer volumes. We have tried to retain core skills through the organisation and to date we have been able to do that."

Stadco said it had recently seen a "plateau" in its volumes after they "fell off a cliff" in January.

Operation director Mark Hemming said: "We have seen a 40 per cent to 60 per cent volume reduction in direct response to our customers building fewer vehicles. We have been fairly successful in retaining the work in the UK, while there is pressure at sourcing work in low cost countries, we have manage to resist that, absolutely.

"We have behaved diligently and that has resulted in losing a lot of good people, but we have worked hard to retain core skills. We absolutely believe that the business will come back. We want to concentrate on coming out the other side, so we are strong and fitter for the market."

Ogihara Europe, of Hortonwood, which supplies several car manufacturers in the UK, has axed about 45 jobs from its 179 workforce, in addition to 45 redundancies announced in April.

Louise Alexander, senior manager human resources, said the losses were down to the "extremely tough economic climate."

She said: "The company is assessing its costs against reduced sales and increasing costs for the remainder of this financial year, with a view to operating with a leaner structure. Regrettably, Ogihara Europe entered into the consultation process with its manufacturing workforce and its recognised trade union - in accordance with its redundancy policy."

Ogihara Corporation is the largest independent supplier of automotive press tooling to the world's car industry. Its European base was formed in Telford in 1995, on the site of the former Venture Pressings operation, to support top European manufacturers like Jaguar, Toyota, Saab and Vauxhall.

Better placed

TI Group Automotive Systems, in Halesfield, makes steel tubing for brake and fuel tank lines. It lost about 100 of its workforce in 2007. Managing director Dave Smith said the initial job losses were due to Peugeot and Ford Transit moving production out of the UK.

"Volumes are significantly down and that's a general cry from all the manufacturers. I guess we are in a little better position because we restructured after the 2007 downswing in volumes.

"That means we are probably better placed to deal with it this time around, we've moved into a smaller factory but that's not to say we're untouched by it."

TMat Morrell, formerly Morrell Products, on Halesfield, is a specialist supplier of noise and thermal insulation and interior trim the automotive, transport, construction and industrial markets.Managing director Jeremy Marshall said its production for the automotive sector had "virtually come to a standstill" in the first quarter of the year.

"Most certainly the situation continues to be extremely difficult and that has resulted in us seeing severe reductions in our production schedule. Fundamentally our production for the automotive customer has stopped, so we have had to restructure with both short term working and a redundancy programme."

Mr Marshall would not confirm exactly how many posts had been lost, but said the 185-strong workforce had gone through two rounds of redundancies.

He said: "I see no particular light at the end of the tunnel in 2009. There may be other areas of opportunities and we are exploring other market sectors and responding to the downturn."

Grainger and Worrall is an aluminium casting company, which provides parts for engines and also developed a range of products specifically for motorsport markets such as Formula 1.

Based at Stanmore Industrial Estate in Bridgnorth, it also has a machining base in Stafford Park, and numbers Bugatti, Bentley and Aston Martin among its clients.

Head of human resources Kirstie Morris said the company had a small number of redundancies at the end of 2008 with some short-time working in operation, but some areas had remained buoyant.

Floform Limited, based in Henfaes Lane, Welshpool entered administration this month with the loss of 74 jobs.

Bosses said the loss of key customers was to blame and continuing to trade was no longer a viable option.

Zolfo Cooper, joint administrators of the company, which has been in Welshpool since 1959, said the slowdown in the motor industry was to blame.

"Those pressures have led many of Floform's customers to significantly reduce their production schedules, resulting in a liquidity crisis for this business."

Welshpool-based Cobra makes interior trim products for the automotive industry. It recently moved into a new facility in Buttington Cross as part of a £4.3 million investment in the company which directors say makes Cobra "a real rival" to its competitors. It supplies General Motors, Volvo and the VW/Audi group among others.

Managing director Gary Seale said his Welsh factory was still on a five-day week.

"But suffering from suppliers going bust, our Whitchurch factory is on a three-day week but we've just started recycling high value polymers to take them back to five days. We will still grow this year but by 35 per cent, not the 90 we predicted."

Midland Alloy, on Stafford Park, was set up in 1973. It is mainly involved in manufacturing windows and windscreens for marine and railway applications. It moved into the automotive sector, producing a range of sunroof frames and windscreens. Bosses did not wish to comment.

Also unavailable was German-owned Mahle Filter Systems which supplies global car brands including BMW, Ford, Aston Martin and Nissan. It is developing its site in Halesfield and plans to create 200 jobs by 2010, bringing the total number of employees to 350.

Integral part

A spokesman said: "We're in line with our forecast, which was a 10 per cent growth for the year. I wouldn't say we're doing ever so well, the UK market is a bit stagnant, but the overseas market is doing well."

Shropshire car component manufacturers attended two recent forums on the crisis where support group Accelerate, together with Business Link in the West Midlands and the Manufacturing Advisory Service, provided help and advice.

Rachel Eade, programme manager at Accelerate, said: "There is so much information flying around the shopfloor and the factories, it is difficult to gain a full picture of what is going on out there. This forum provided first-hand insight into exactly how companies are coping and, importantly, what we can do to help. Advantage West Midlands has already launched the Transition Fund, which provides loans to viable businesses ranging from £50,000 to £250,000."

Richard Crooks, of Business Link, said: "The automotive sector is an integral part of our regional economy and we need to ensure that the skills we have built up over many years are not lost for the future.

"Our role is to make sure we work with partners like Accelerate to deliver the very best business support that helps suppliers emerge from these difficult times stronger and more competitive than ever before."